CORPORATE ACTION

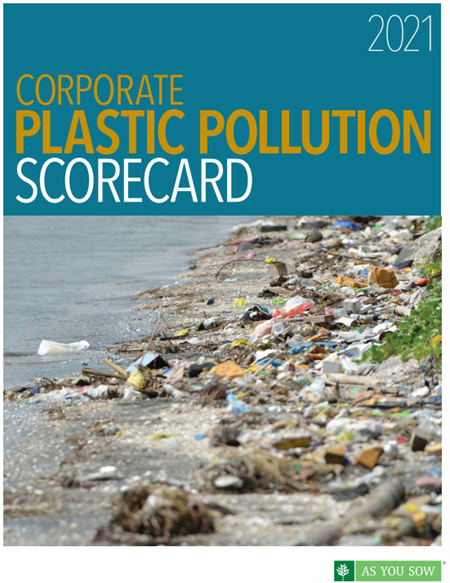

Scorecard Highlights Companies’ Goals And Things To Do To Cut Plastic Pollution

Companies are starting to take steps to deal with plastic pollution, according to the report Corporate Plastic Pollution Scorecard, 2021. However, the fact that only one company earned the highest grade of B highlights the need for all companies to do significantly more to reduce, if not eliminate, the environmental and financial impact of plastic pollution. The report focuses only on the companies’ sustainability goals, including reduction of plastic pollution, but it is up to investors, governments, and the public to hold companies responsible for meeting such goals. Highlights of the report include a “ninefold increase” in plastic reduction goals and almost “fourfold increase” in support for expanded manufacturer responsibility.[Image Credit: © As You Sow]

CORPORATE ACTION: Coca-Cola

Coca-Cola Introduces Next-Generation 100% Plant-Based Plastic Bottle

Coca-Cola has introduced a prototype of its next-generation bottle made from 100% plant-based plastic (bPET), excluding cap and label. The company said the bottle is made using technologies that are currently ready for commercial-scale application. Also, the company revealed that the proposed manufacturing process is based on a technology announced earlier for converting second-generation biomass to plant-based monoethylene glycol, one of the two molecules required to manufacture bPET.[Image Credit: © Coca-Cola Company]

Coca-Cola has introduced a prototype of its next-generation bottle made from 100% plant-based plastic (bPET), excluding cap and label. The company said the bottle is made using technologies that are currently ready for commercial-scale application. Also, the company revealed that the proposed manufacturing process is based on a technology announced earlier for converting second-generation biomass to plant-based monoethylene glycol, one of the two molecules required to manufacture bPET.[Image Credit: © Coca-Cola Company]

CORPORATE ACTION: Henkel

Beauty Industry Aims To Create Safety Standards For Recycled Plastic Packaging

Industry consortium CosPaTox, which stands for cosmetics, packaging, and toxicology, is seeking to develop safety standards for post-consumer plastic recyclate for packaging of cosmetics and cleaning products. The beauty industry currently lacks industrywide safety standards for recycled plastic packaging. The consortium aims to focus on chemicals that come with recycled resin that could adversely affect the skin, to resolve this issue and consequently encourage manufacturers and brands to increase their use of recycled plastic packaging. [Image Credit: © Henkel]

Industry consortium CosPaTox, which stands for cosmetics, packaging, and toxicology, is seeking to develop safety standards for post-consumer plastic recyclate for packaging of cosmetics and cleaning products. The beauty industry currently lacks industrywide safety standards for recycled plastic packaging. The consortium aims to focus on chemicals that come with recycled resin that could adversely affect the skin, to resolve this issue and consequently encourage manufacturers and brands to increase their use of recycled plastic packaging. [Image Credit: © Henkel]

CORPORATE ACTION: Procter & Gamble

P&G Announces Winners Of It’s Our Home Awards

Procter & Gamble has announced the winners of the company’s 2021 It’s Our Home Awards, which aim to recognize sustainability milestones reached by the company’s supply chain and operations units. P&G China received honors for its Big and Little Green Treasure Boxes reusable packaging, while Global Energy Purchases, with its Renewable Electricity Acceleration Project, has helped P&G reach 97% renewable electricity coverage worldwide.[Image Credit: © Procter & Gamble]

CORPORATE ACTION: Other

SC Johnson Joins Forces With La Anónima And CEMPRE to Promote Recycling In Argentina

SC Johnson has partnered with Argentina-based retailer La Anónima and environmental group Compromiso Empresarial para el Reciclaje (CEMPRE) to increase recycling levels and collect more plastic and other recyclable waste in the Patagonia region of the country and Chile. The collaboration deal calls for the setting up of an ecopoint, or collection center, to be located near Muelle Comandante Piedra Buena to provide consumers with better access to recycling facilities. The ecopoint is made of 100% recycled plastic and features a roof made of polyaluminum from recycled tetrabrik containers.[Image Credit: © SC Johnson]

SC Johnson has partnered with Argentina-based retailer La Anónima and environmental group Compromiso Empresarial para el Reciclaje (CEMPRE) to increase recycling levels and collect more plastic and other recyclable waste in the Patagonia region of the country and Chile. The collaboration deal calls for the setting up of an ecopoint, or collection center, to be located near Muelle Comandante Piedra Buena to provide consumers with better access to recycling facilities. The ecopoint is made of 100% recycled plastic and features a roof made of polyaluminum from recycled tetrabrik containers.[Image Credit: © SC Johnson]

Asda Opens Largest Store Offering Product Refill Service In UK

Asda has opened the largest store that offers product refill service in the UK. The store is located at Monk’s Cross in York and comes with 18 refill bays for refilling more than 100 branded and private-label products. The loose and unpackaged range covers branded products, such as Yorkshire Tea and Kellogg’s cereals, and Asda-brand cereals and pasta.[Image Credit: © Asda]

General Mills Launches $500 Million Sustainability-Linked Bond

General Mills announced its $500 million sustainability-linked bond as part of its efforts on preventing climate change. The bond is linked to its quantifiable achievements in reducing greenhouse gas emissions by 30% across General Mills’s value chain by 2030. Bond investors will see higher interest rates should the company fail to reach interim reduction targets by 2025.[Image Credit: © General Mills]

Costa Coffee Tries BURT Reusable Cup Scheme In Glasgow

Costa Coffee is testing its Borrow, Use, Reuse, Take Back or BURT program, which uses a new blockchain technology to encourage consumers to reuse coffee cups. The trial will run for six months in Glasgow and will provide the company with feedback from customers regarding uptake and behavior toward reusable cups. Customers can join the scheme by scanning a QR code at a Costa Coffee store and providing a one-time payment of £5.[Image Credit: © Costa Coffee]

Costa Coffee is testing its Borrow, Use, Reuse, Take Back or BURT program, which uses a new blockchain technology to encourage consumers to reuse coffee cups. The trial will run for six months in Glasgow and will provide the company with feedback from customers regarding uptake and behavior toward reusable cups. Customers can join the scheme by scanning a QR code at a Costa Coffee store and providing a one-time payment of £5.[Image Credit: © Costa Coffee]

MARKET NEWS

Smaller Brands Lead Beauty Industry Toward Adopting Sustainable Materials And Packaging

Independent cosmetics brands are in some cases moving faster than their mass-market counterparts in integrating sustainable ingredients and packaging into their products. Indie Beauty Expo co-founder Jillian Wright said that as concerns over climate change and pollution are prompting cosmetics manufacturers to adopt more environment-friendly practices, the independent, smaller brands are “well positioned to pivot” to biodegradable ingredients and packaging. Smaller brands, however, faced obstacles in working with sustainable alternatives, including access to eco-friendly packaging and ingredient supply chains.[Image Credit: © SookyungAn]

Independent cosmetics brands are in some cases moving faster than their mass-market counterparts in integrating sustainable ingredients and packaging into their products. Indie Beauty Expo co-founder Jillian Wright said that as concerns over climate change and pollution are prompting cosmetics manufacturers to adopt more environment-friendly practices, the independent, smaller brands are “well positioned to pivot” to biodegradable ingredients and packaging. Smaller brands, however, faced obstacles in working with sustainable alternatives, including access to eco-friendly packaging and ingredient supply chains.[Image Credit: © SookyungAn]

APC Packaging Launches Earth-Friendly Dropper-And-Bottle Packaging

APC Packaging said it has launched the Mono-Material System Dropper & Bottle packaging. The company said the product is designed to promote sustainability while allowing clients to customize their offering. Also, the company designed the pipette to be built without glass, unlike similar products that are multi-material and non-recyclable.[Image Credit: © APC Packaging ]

Loop Sees Growing Adoption Of Its Reusable Packaging Model

New Jersey-based TerraCycle’s Loop division makes reusable plastic packaging designed to help manufacturers and retailers reduce plastic packaging waste. In collaboration with leading manufacturers, Loop offers hundreds of ordinary products, including disinfecting wipes and bathroom cleaners, in heavy-duty containers that can last through 10 or more cycles. Loop’s system encourages shoppers to return empty containers to a Loop bin. Loop has moved its operations from an online experiment to a real-world, in-store option as a growing number of manufacturers and retailers are supporting the reuse system.[Image Credit: © Loop]

New Jersey-based TerraCycle’s Loop division makes reusable plastic packaging designed to help manufacturers and retailers reduce plastic packaging waste. In collaboration with leading manufacturers, Loop offers hundreds of ordinary products, including disinfecting wipes and bathroom cleaners, in heavy-duty containers that can last through 10 or more cycles. Loop’s system encourages shoppers to return empty containers to a Loop bin. Loop has moved its operations from an online experiment to a real-world, in-store option as a growing number of manufacturers and retailers are supporting the reuse system.[Image Credit: © Loop]

INNOVATION & TECHNOLOGY

Nextek’s NEXTLOOP Posts 99.9% Accuracy In Sorting Food Packaging Waste During Trials In Germany

Nextek Limited’s NEXTLOOP recycling project has reported 99.9% sorting purity from its tracer-based sorting test run at TOMRA in Germany. Results of the sorting trials highlighted the efficiency of Nextek’s technology in sorting food packaging from non-food packaging, meeting the standards set by the Food Standards Authorities in both the UK and EU.[Image Credit: © Nextek Limited]

Microwave-Induced Pyrolysis Offers Way To Recycle Flexible Plastic

Carlos Ludlow Palafox, founder and director of Huntingdon, UK-based Enval Ltd., is pushing a microwave-induced pyrolysis technology for recycling flexible plastic packaging. He said chemical recycling technologies should be employed to reuse flexible plastic, which took significant time and money to develop and has been so effective in keeping food products safe. Conventional pyrolysis technologies are not financially feasible as a means of recycling flexible plastic, but microwave-induced pyrolysis seems ready to process materials that are not currently recyclable.[Image Credit: © Enval Ltd.]

Carlos Ludlow Palafox, founder and director of Huntingdon, UK-based Enval Ltd., is pushing a microwave-induced pyrolysis technology for recycling flexible plastic packaging. He said chemical recycling technologies should be employed to reuse flexible plastic, which took significant time and money to develop and has been so effective in keeping food products safe. Conventional pyrolysis technologies are not financially feasible as a means of recycling flexible plastic, but microwave-induced pyrolysis seems ready to process materials that are not currently recyclable.[Image Credit: © Enval Ltd.]

Startups And Innovators Seek To Develop Plastic Alternatives

Business startups, such as Apeel, and scientific projects are working to develop materials designed to replace conventional single-use plastic packaging. Apeel has developed an “edible, tasteless and invisible plant-based spray” for produce, including fruits and vegetables. These companies’ approaches vary in resolving the problem of fossil-based plastic. Bioplastics is one of the most popular alternatives, but it currently accounts for only 1% of the market. Also, the sustainability claims of proposed alternatives sometimes fall short when subjected to objective and real-world testing.[Image Credit: © Apeel]

Business startups, such as Apeel, and scientific projects are working to develop materials designed to replace conventional single-use plastic packaging. Apeel has developed an “edible, tasteless and invisible plant-based spray” for produce, including fruits and vegetables. These companies’ approaches vary in resolving the problem of fossil-based plastic. Bioplastics is one of the most popular alternatives, but it currently accounts for only 1% of the market. Also, the sustainability claims of proposed alternatives sometimes fall short when subjected to objective and real-world testing.[Image Credit: © Apeel]

Alternative Plastics Wins 2021 Carrefour Innovation Competition With Algae-Based Garbage Bags

Alternative Plastics has won the Carrefour Innovation Prize 2021 with the company’s Alg&Bag line of garbage bags. Alternative Plastics makes the garbage bags using Eranova’s green algae formulation in France. The annual competition is organized by Carrefour, one of France’s largest retailers, for small and medium-sized companies. The garbage bags are presented as an example of the circular economy and companies’ actions related to environmental responsibility.[Image Credit: © Alternative Plastics]

Alternative Plastics has won the Carrefour Innovation Prize 2021 with the company’s Alg&Bag line of garbage bags. Alternative Plastics makes the garbage bags using Eranova’s green algae formulation in France. The annual competition is organized by Carrefour, one of France’s largest retailers, for small and medium-sized companies. The garbage bags are presented as an example of the circular economy and companies’ actions related to environmental responsibility.[Image Credit: © Alternative Plastics]

Woodly Offers Wood-Based Clear Plastic As Sustainable Packaging Material

Woodly Ltd. offers Woodly, a clear plastic material made from wood cellulose, as a sustainable packaging option. Woodly has developed and patented the technology or recipe for making the packaging material; however, instead of producing the product, the company markets it as a raw material for packaging. Customers can manufacture Woodly material using their existing factories and machines.[Image Credit: © Woodly Ltd. ]

Woodly Ltd. offers Woodly, a clear plastic material made from wood cellulose, as a sustainable packaging option. Woodly has developed and patented the technology or recipe for making the packaging material; however, instead of producing the product, the company markets it as a raw material for packaging. Customers can manufacture Woodly material using their existing factories and machines.[Image Credit: © Woodly Ltd. ]

Mushroom Material Offers Mushroom-Based Material As Sustainable Packaging Alternative

Mushroom Material, a start-up from New Zealand, has created a sustainable packaging material derived from mushroom. The company offers the packaging material, made by combining the roots of mushroom with organic agricultural wastes, such as saw dust and hemp hulls, as an alternative to polystyrene Styrofoam and cardboard packaging. The company said the material is strong enough to endure impacts but takes only six weeks to biodegrade.[Image Credit: © Mushroom Material]

EMERGING IDEAS, THEMES & TRENDS

EPO Says Europe And US Lead World In Patenting Of Recycling And Alternative Plastics

Europe and the US are leading the world in terms of innovation in plastic recycling and alternative plastics technologies, according to the European Patent Office or EPO. Details of the EPO’s latest report, “Patents for tomorrow’s plastics: Global innovation trends in recycling, circular design and alternative sources,” revealed that Europe and the US accounted for 30% each of related patents worldwide in 2010 to 2019. Germany accounted for 8% of global total. Chemical and biological recycling methods produced the most patenting activity during the period covered by the report.[Image Credit: © European Patent Office]

Europe and the US are leading the world in terms of innovation in plastic recycling and alternative plastics technologies, according to the European Patent Office or EPO. Details of the EPO’s latest report, “Patents for tomorrow’s plastics: Global innovation trends in recycling, circular design and alternative sources,” revealed that Europe and the US accounted for 30% each of related patents worldwide in 2010 to 2019. Germany accounted for 8% of global total. Chemical and biological recycling methods produced the most patenting activity during the period covered by the report.[Image Credit: © European Patent Office]

New Study Claims Concept Of Circular Economy Lacks Clarity And Substance

Researchers from Lancaster University Management School, Lund University, and Sweden’s Royal Institute of Technology have said that the definition of a “circular economy” lacks clarity and substance. Their study, published in Journal of Industrial Ecology, claims the concept of circular economy is too expansive and makes it impossible to measure its impact. The researchers also claim that the concept has failed to consider physical laws regarding the “physical limitations of materials” and the “complexity of the waste”.[Image Credit: © Wiley]

OTHER NEWS

Retailers Need To Focus On Packaging And Return Logistics To Complete Circularity

Retailers can reduce waste from returns and excess inventories by focusing on packaging and return logistics. The COVID pandemic has driven growth in ecommerce, which in turn, has caused an explosion in volumes of packaging used to ship, transport, and sell items online. Also, retailers can reduce supply-chain waste by coming up with solutions for return logistics. Retailers need to adopt circularity in their business models in order to keep retail returns and excess inventories from ending up in landfills.[Image Credit: © Sustainable Brands]

Retailers can reduce waste from returns and excess inventories by focusing on packaging and return logistics. The COVID pandemic has driven growth in ecommerce, which in turn, has caused an explosion in volumes of packaging used to ship, transport, and sell items online. Also, retailers can reduce supply-chain waste by coming up with solutions for return logistics. Retailers need to adopt circularity in their business models in order to keep retail returns and excess inventories from ending up in landfills.[Image Credit: © Sustainable Brands]

Copyright 2026 Business360, Inc.