CORPORATE ACTION: Clorox

Clorox Highlights Several Sustainable And Earth-Friendly Products

Clorox has been offering several environment-friendly products that are made from sustainable and recycled materials. These include the Clorox Refillable Cleaner, which comes with a reusable spray bottle and concentrated refill pods. The company also offers Clorox cleaning spray bottles with perforations to the shrink labels, making it easier to recycle the plastic bottles. Also, the company offers the Glad ForceFlex Plus Tall Kitchen Drawstring Trash Bags made with 50% recovered plastic.[Image Credit: © The Clorox Company]

CORPORATE ACTION: Coca-Cola

Coca-Cola Unveils Ambitious Reusable-Packaging Targets For 2030

Coca-Cola Company has announced its goal to significantly increase its use of reusable packaging by 2030. As part of the company’s World Without Waste initiative, Coca-Cola will make all its primary consumer packaging recyclable by 2025, with 50% using recycled material by 2030. The company also aims to collect and recycle a bottle or can for every beverage it sells by 2030.[Image Credit: © Coca-Cola Company]

CORPORATE ACTION: Colgate

Colgate Rolls Out Recyclable HDPE Toothpaste Tubes

Colgate is launching a recyclable toothpaste tube made from High Density Polyethylene (HDPE) plastic. The process of recycling the HDPE toothpaste tubes does not require additional steps, such as rinsing, cutting, or cleaning. The tubes come with “Recycle Me!” graphics to alert both consumers and operators of Materials Recovery Facilities that the toothpaste containers are recyclable.[Image Credit: © Colgate ]

CORPORATE ACTION: Henkel

Henkel Launches Line Of Pril Dishwashing Detergent With Sustainable Refillable Packaging

Henkel’s Pril Stark & Natürlich line of dishwashing detergent comes in a refillable pump dispenser, with a bottle made from recycled plastic and refill pouch with 70% less plastic. The dishwashing formula contains 93% ingredients from natural sources and food-certified colorants and fragrances. Henkel developed the product formula and packaging in close collaboration with consumers through consumer tests, trend research, and online and offline interviews. The pouch is the result of a partnership with packaging group Mondi and features a pump design that completely empties the bottle, leaving no residue.[Image Credit: © Henkel]

Henkel’s Pril Stark & Natürlich line of dishwashing detergent comes in a refillable pump dispenser, with a bottle made from recycled plastic and refill pouch with 70% less plastic. The dishwashing formula contains 93% ingredients from natural sources and food-certified colorants and fragrances. Henkel developed the product formula and packaging in close collaboration with consumers through consumer tests, trend research, and online and offline interviews. The pouch is the result of a partnership with packaging group Mondi and features a pump design that completely empties the bottle, leaving no residue.[Image Credit: © Henkel]

Henkel Rewards Leading Suppliers For 2021

Henkel held an event recognizing its 2021 top suppliers on February 7, 2022. The top suppliers were awarded in five categories. Sasol received the Sustainability Award from Henkel Beauty Care, while Firmenich and Takasago earned the Sustainability Award from Laundry & Home Care. BASF received the Best Innovation Contributor from Beauty Care and Laundry & Home Care, while Evonik received the Supply Resilience Award.[Image Credit: © Henkel ]

Henkel held an event recognizing its 2021 top suppliers on February 7, 2022. The top suppliers were awarded in five categories. Sasol received the Sustainability Award from Henkel Beauty Care, while Firmenich and Takasago earned the Sustainability Award from Laundry & Home Care. BASF received the Best Innovation Contributor from Beauty Care and Laundry & Home Care, while Evonik received the Supply Resilience Award.[Image Credit: © Henkel ]

CORPORATE ACTION: Kao

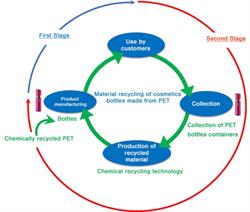

Kao Tests In-Store Collection And Recycling Program For Used Cosmetics Bottles In Japan

Kao Corporation is testing a program aimed at collecting used plastic cosmetic bottles and recycling them into new bottles. The “field testing” will run through July 31, 2022 in partnership with retailer AEON in Japan’s Kanto region and COLOR STUDIO cosmetics retail stores in AEON malls. The company will use JEPLAN, Inc.’s BRING Technology chemical recycling technology.[Image Credit: © Kao Corporation]

CORPORATE ACTION: PepsiCo

PepsiCo Makes Earth-Friendly Pallets Made Of UBQ Material

PepsiCo announced it will start using the UBQ material developed by an Israel-based business startup of thesame name to make pallets made of unsorted household waste. PepsiCo’s partner, Ecoboxes Embalagens Plásticas, developed the pallets. UBQ material is a bio-based thermoplastic made from 100% unsorted solid wastes, such as mixed plastics, paper, cardboard, and organics.[Image Credit: © Divulgação PepsiCo]

PepsiCo announced it will start using the UBQ material developed by an Israel-based business startup of thesame name to make pallets made of unsorted household waste. PepsiCo’s partner, Ecoboxes Embalagens Plásticas, developed the pallets. UBQ material is a bio-based thermoplastic made from 100% unsorted solid wastes, such as mixed plastics, paper, cardboard, and organics.[Image Credit: © Divulgação PepsiCo]

Kao Stops Making Products With Polluting Plastic Stickers

Kao Corporation stopped manufacturing products with attached plastic stickers in December 2021. The move is part of the company’s efforts to achieve its Zero Waste objective by 2021. Kao previously used “eye-catching” plastic stickers to provide consumers with information about product features and proper product usage.[Image Credit: © Kao Corporation]

Kao Corporation stopped manufacturing products with attached plastic stickers in December 2021. The move is part of the company’s efforts to achieve its Zero Waste objective by 2021. Kao previously used “eye-catching” plastic stickers to provide consumers with information about product features and proper product usage.[Image Credit: © Kao Corporation]

PepsiCo Plans To Stop Using Virgin Plastic Packaging For Crisp And Chip Products in Europe

PepsiCo Europe announced its plan to stop using virgin plastic packaging for its crisp and chip products by 2030. The company expects to reduce greenhouse gas emissions from film packaging by up to 40% and said it will work to develop a circular economy for flexible packaging in the European market through “design, infrastructure, and giving packaging materials a new life”. This initiative is part of the company’s PepsiCo Positive sustainability program.[Image Credit: © PepsiCo]

PepsiCo Europe announced its plan to stop using virgin plastic packaging for its crisp and chip products by 2030. The company expects to reduce greenhouse gas emissions from film packaging by up to 40% and said it will work to develop a circular economy for flexible packaging in the European market through “design, infrastructure, and giving packaging materials a new life”. This initiative is part of the company’s PepsiCo Positive sustainability program.[Image Credit: © PepsiCo]

CORPORATE ACTION: Reckitt Benckiser

Reckitt Joins Forces With RecyClass To Achieve Sustainable Packaging Goals

Reckitt has partnered with recycling group RecyClass to help achieve its goal of reducing the use of virgin plastic in packaging by 50% by 2030 and ensuring its plastic packaging is 100% recyclable or reusable by 2025. The company also aims to include 25% of recycled content in its plastic packaging by 2025. RecyClass aims to promote the recycling of plastic packaging and create a coordinated approach to calculation and traceability of recycled content in Europe.[Image Credit: © Reckitt plc]

Reckitt Updates Supplier Sustainability Policies

Reckitt has announced its Sourcing for Sustainable Growth Policy, the company’s updated supplier sustainability policies. The company said the new policies apply to all the company’s supply chain partners, including third-party manufacturers, raw and packaging material suppliers, and service providers. Also covered by the new policies are vendors and traders, agents and contractors, as well as joint venture partners.[Image Credit: © Reckitt plc]

CORPORATE ACTION: Tesco

Henkel Gets Closer To 2025 Sustainable Packaging Targets

Henkel’s 100-50-zero strategy requires the company by 2025 to have 100% reusable or recyclable packaging, 50% less virgin plastic in packaging, and zero plastic waste. At present, the company has achieved 89% reusable or recyclable packaging within its laundry and home care department. The company is also adding more recycled plastic to packaging and working to make recycled packaging more attractive to consumers.[Image Credit: © Henkel]

Henkel’s 100-50-zero strategy requires the company by 2025 to have 100% reusable or recyclable packaging, 50% less virgin plastic in packaging, and zero plastic waste. At present, the company has achieved 89% reusable or recyclable packaging within its laundry and home care department. The company is also adding more recycled plastic to packaging and working to make recycled packaging more attractive to consumers.[Image Credit: © Henkel]

Henkel Highlights Beauty Industry Pursuit Of Sustainable Packaging

In an article from its Spotlight Magazine, Henkel said manufacturers of cosmetics and skincare products face many challenges in adopting sustainable packaging. Each year, the beauty industry produces billions of units of packaging that are some of the hardest to recycle. The trade group CosPaTox is working to develop safety standards of post-consumer plastic recyclates (PCR) for cosmetic and cleaning product packaging.[Image Credit: © Henkel (Sandra Breuer)]

Tesco Relies On 4Rs To Promote Sustainable Packaging

.jpg&width=250&height=232)

Tesco’s strategy for sustainable packaging is based on 4Rs: Remove, Reduce, Reuse, and Recycle. Tesco head of packaging, James Bull, explained this as “remove where we can, reduce it where we can’t, reuse more of it, and recycle what’s left”. To date, Tesco has improved the sustainability of more than 1,600 products and saved over 6,000 tons of material. Tesco launched its preferred material list in 2018 in order to simplify the retailer’s packaging portfolio and promote circularity.[Image Credit: © Tesco plc]

CORPORATE ACTION: Unilever

Unilever Worked With Silgan To Make Fully Recyclable Spray Bottles

Unilever collaborated with supplier Silgan to develop a new recyclable trigger for the spray mechanism of spray bottles for cleaning products. The company wanted the trigger to have components made from either polypropylene (PP) or polyethylene (PE) polymers to make the spray bottles fully recyclable. Unilever also had to change the design of the spring component to achieve full functionality.[Image Credit: © Unilever plc]

Unilever Is Rethinking Plastic Packaging

In a series of articles, Unilever explains how it’s “completely rethinking the role of plastic in our business”, by answering common consumer questions, such as on the company’s use of plastic sachets, and why plastic packaging is needed at all. It says that plastic sachets offer advantages in packaging but are very hard to recycle. It is promoting refill solutions to address the problem and testing non-plastic materials for use as sachets.

In a series of articles, Unilever explains how it’s “completely rethinking the role of plastic in our business”, by answering common consumer questions, such as on the company’s use of plastic sachets, and why plastic packaging is needed at all. It says that plastic sachets offer advantages in packaging but are very hard to recycle. It is promoting refill solutions to address the problem and testing non-plastic materials for use as sachets.The company also discusses the steps it’s taking to make its packaging recyclable and using post-consumer recycled (PCR) plastic in new packaging, raising the issue of availability of PCR on the market and the need to help collect and process more plastic packaging. It is working with the UN Development Programme to protect the livelihood of informal waste collectors in India. Unilever also presents ways in which it’s making packaging reusable, by experimenting with reusable bottles and refill systems for cleaning and laundry products, testing in-store refill stations, and working with partners to develop refill and reuse systems.[Image Credit: © Unilever plc]

CORPORATE ACTION: Other

Kroger Works With Loop To Offer In-Store Reusable Service In Portland Area

Kroger has partnered with TerraCycle’s Loop circular reuse platform to launch an in-store reuse service at 25 Fred Meyer grocery stores in Portland, Oregon. Loop collaborated with 10 brands to come up with 20 products that come in reusable containers. The product list includes Stubb’s barbecue sauce, Nature’s Path granola, and Pantene shampoo and conditioner.[Image Credit: © Kroger and Loop]

Shiseido Buys Stake In R Plus Japan

Shiseido Company, Limited, will invest in R Plus Japan Limited, a company developing a recycling technology for used plastics with reduced environmental impact. R Plus Japan is collaborating with U.S.-based biochemical venture company Anellotech Inc. to commercialize the technology by 2027, working with companies from other industries.Anellotech’s Plas-TCat chemical recycling technology uses a one-step thermal-catalytic process.[Image Credit: © Shiseido Company]

Shiseido Company, Limited, will invest in R Plus Japan Limited, a company developing a recycling technology for used plastics with reduced environmental impact. R Plus Japan is collaborating with U.S.-based biochemical venture company Anellotech Inc. to commercialize the technology by 2027, working with companies from other industries.Anellotech’s Plas-TCat chemical recycling technology uses a one-step thermal-catalytic process.[Image Credit: © Shiseido Company]

CAMPAIGNS, COMMITMENTS & NGOs

Latin American And The Caribbean Circular Economy Coalition Reveals Vision

.png&width=250&height=82) The Latin American and the Caribbean Circular Economy Coalition has unveiled the group’s shared vision for a circular economy in the region. The organization said the shared vision will help promote “alignment and cooperation” among the region’s countries and provide a framework for future sustainability projects. The vision is formulated according to the region’s socio-economic characteristics and different cultures.[Image Credit: © Ellen MacArthur Foundation]

The Latin American and the Caribbean Circular Economy Coalition has unveiled the group’s shared vision for a circular economy in the region. The organization said the shared vision will help promote “alignment and cooperation” among the region’s countries and provide a framework for future sustainability projects. The vision is formulated according to the region’s socio-economic characteristics and different cultures.[Image Credit: © Ellen MacArthur Foundation]

Leading Beauty Brands Join EcoBeautyScore Consortium To Develop Industry’s Sustainability Evaluation Tool

The EcoBeautyScore Consortium has gathered 36 cosmetics and personal care companies and professional groups, including L’Oréal and Unilever, to provide consumers with more environment-friendly product choices. The organization is working with sustainability consulting firm Quantis to develop an environmental impact evaluation and scoring scheme for cosmetic and personal care products for the industry. The planned system will include a common method for evaluating products’ environmental impact and a common database of the environmental impact of standard ingredients.[Image Credit: © AP Group]

The EcoBeautyScore Consortium has gathered 36 cosmetics and personal care companies and professional groups, including L’Oréal and Unilever, to provide consumers with more environment-friendly product choices. The organization is working with sustainability consulting firm Quantis to develop an environmental impact evaluation and scoring scheme for cosmetic and personal care products for the industry. The planned system will include a common method for evaluating products’ environmental impact and a common database of the environmental impact of standard ingredients.[Image Credit: © AP Group]

UK Needs To Address Barriers To Reuse Adoption

The UK government needs to act to help overcome factors that hinder popular adoption of reuse as a means of reducing waste and promoting sustainability. Reuse is expected to remain a labor-intensive activity because of the wide range of products currently on the market. Other obstacles include “social preferences and attitudes”, such as peer pressure to use new products in developed countries. There are also calls for the UK to stop blaming the pandemic for its failure to protect the environment and to act immediately.[Image Credit: © Shirley810 ]

The UK government needs to act to help overcome factors that hinder popular adoption of reuse as a means of reducing waste and promoting sustainability. Reuse is expected to remain a labor-intensive activity because of the wide range of products currently on the market. Other obstacles include “social preferences and attitudes”, such as peer pressure to use new products in developed countries. There are also calls for the UK to stop blaming the pandemic for its failure to protect the environment and to act immediately.[Image Credit: © Shirley810 ]

Ecosurety Exploration Fund Announces Winning Reuse And Recycling Innovations

Ellen MacArthur Foundation, World Wildlife Fund Issue Joint Call For UN Plastic Pollution Treaty

.png&width=250&height=82) The Ellen MacArthur Foundation has partnered with the World Wildlife Fund to call on the United Nations to enact a legally binding treaty on plastic pollution. The foundation asserted that voluntary agreements and current measures cannot solve the fast-growing and worsening global plastic pollution crisis. The partners are calling for a plastic treaty that will include a “clear focus on ways” to stop the problem before it starts, global standards and support for all countries to do their part.[Image Credit: © Ellen MacArthur Foundation ]

The Ellen MacArthur Foundation has partnered with the World Wildlife Fund to call on the United Nations to enact a legally binding treaty on plastic pollution. The foundation asserted that voluntary agreements and current measures cannot solve the fast-growing and worsening global plastic pollution crisis. The partners are calling for a plastic treaty that will include a “clear focus on ways” to stop the problem before it starts, global standards and support for all countries to do their part.[Image Credit: © Ellen MacArthur Foundation ]

U.S. Plastics Pact Releases List Of Non-Sustainable Packaging Materials

The U.S. Plastics Pact released its Problematic and Unnecessary Materials List, which identifies 11 materials presently not reusable, recyclable, or compostable. It’s a first step toward speeding the adoption of a circular economy in the country and part of the group’s Roadmap to 2025 objective that seeks to publish a list of packaging materials that are not environment-friendly and sustainable. The list includes cutlery, non-detectable pigments and problematic label constructions.[Image Credit: © U.S. Plastics Pact]

The U.S. Plastics Pact released its Problematic and Unnecessary Materials List, which identifies 11 materials presently not reusable, recyclable, or compostable. It’s a first step toward speeding the adoption of a circular economy in the country and part of the group’s Roadmap to 2025 objective that seeks to publish a list of packaging materials that are not environment-friendly and sustainable. The list includes cutlery, non-detectable pigments and problematic label constructions.[Image Credit: © U.S. Plastics Pact]

MARKET NEWS

Impact Recycling Builds Facility For Hard-To-Recycle Plastic Wastes In Scotland

Which? Names Lidl, Waitrose As UK’s Most Sustainable Retailers

Consumer protection group Which? has named Lidl and Waitrose as the “greenest” or most environment-friendly supermarket chains in the UK. Data from the group’s research revealed that Lidl “scored highly for its low greenhouse gas emissions and targets”, while Waitrose performed “consistently well” across all categories. Asda and Sainsbury’s are tied in third place.[Image Credit: © Which?]

ZenWTR Says It’s The World’s First Beverage Brand Certified Plastic Negative

ZenWTR said it has become the first beverage brand in the world to earn the Plastic Negative Brand Certification from the Plastic Credit Exchange. The company said this achievement also marks its commitment to turning all its product lines into plastic negative and promised to support programs that “recover and recycle at least 200%” of its yearly plastic use, starting in 2021.[Image Credit: © ZenWTR]

Corporate Knight’s 2022 Most Sustainable Companies List Includes 10 Consumer Goods Manufacturers

Corporate Knight has released its 2022 Global 100 list of the world’s most sustainable companies. It includes 10 consumer goods companies that have exhibited higher investor returns while demonstrating “strong performance” regarding environmental, social, and governance criteria. McCormick & Company Inc. ranked 6th and Kering SA is in the spot below. Church & Dwight is not ranked in the top 100.[Image Credit: © Corporate Knight]

Corporate Knight has released its 2022 Global 100 list of the world’s most sustainable companies. It includes 10 consumer goods companies that have exhibited higher investor returns while demonstrating “strong performance” regarding environmental, social, and governance criteria. McCormick & Company Inc. ranked 6th and Kering SA is in the spot below. Church & Dwight is not ranked in the top 100.[Image Credit: © Corporate Knight]

INNOVATION & TECHNOLOGY

University Of Birmingham Allows Stopford To Use Supercritical Water Plastic Recycling Technology

The University of Birmingham in the U.K. has licensed the rights to a “supercritical water” technology for recycling plastic waste to engineering and consulting firm Stopford. Bushra Al-Duri from the university’s School of Chemical Engineering invented the technology, which uses water above the critical point of 374.5 degrees Celsius and 220 bars of atmosphere to recycle mixed plastic packaging. Stopford plans to develop further and scale the hydro-thermal process called CircuPlast.[Image Credit: © Filmbetrachter ]

The University of Birmingham in the U.K. has licensed the rights to a “supercritical water” technology for recycling plastic waste to engineering and consulting firm Stopford. Bushra Al-Duri from the university’s School of Chemical Engineering invented the technology, which uses water above the critical point of 374.5 degrees Celsius and 220 bars of atmosphere to recycle mixed plastic packaging. Stopford plans to develop further and scale the hydro-thermal process called CircuPlast.[Image Credit: © Filmbetrachter ]

EMERGING IDEAS, THEMES & TRENDS

Canidae Partners With Petco To Launch In-Store Dog Food Refill Stations

Pet food company Canidae announced the launch of the Kibble Refill Stations at participating Petco pet care facilities across the US. The company said it expects the system to remove 50,000 dog food bags that would otherwise go to landfills during the first year of operation. The refill stations work with a reusable zipper bag, eliminating the need for single-use reinforced bags and helping customers save money.[Image Credit: © Canidae ]

RESEARCH

OECD Countries Produce Almost Half Of World’s Annual Plastic Waste

The fewer than 40 Organization for Economic Cooperation and Development (OECD) countries account for almost 50% of plastic produced worldwide each year. Data from the OECD’s first Global Plastics Outlook report also revealed that the world is producing twice as much plastic waste as two decades ago. Only 9% of the total waste produced is successfully recycled, while 22% is “mismanaged”. The report also showed that the COVID-19 pandemic caused a 2.2% decline in plastics use in 2020; however, plastic littering increased. The global economy rebounded in 2021, causing an increase in plastics consumption.[Image Credit: © OECD]

The fewer than 40 Organization for Economic Cooperation and Development (OECD) countries account for almost 50% of plastic produced worldwide each year. Data from the OECD’s first Global Plastics Outlook report also revealed that the world is producing twice as much plastic waste as two decades ago. Only 9% of the total waste produced is successfully recycled, while 22% is “mismanaged”. The report also showed that the COVID-19 pandemic caused a 2.2% decline in plastics use in 2020; however, plastic littering increased. The global economy rebounded in 2021, causing an increase in plastics consumption.[Image Credit: © OECD]

Oregon State University Researchers Get Closer To Sustainable Packaging From Apple Waste

Scientists from Oregon State University published a paper in the journal “Food and Bioproducts Processing,” highlighting an advance in converting apple waste into environment-friendly packaging material. Research leader Yanyun Zhao studied apple pomace and other by-products from fruit and vegetable processing and juice and wine making. The team received a patent for the research and believe apple pomace can be the “main ingredient” for molded pulp packaging products, such as take-out containers and beverage cartons. Researchers must improve water resistance of pomace and other paper-based packaging to turn it into a viable alternative to plastic.[Image Credit: © Schlumpf98]

Scientists from Oregon State University published a paper in the journal “Food and Bioproducts Processing,” highlighting an advance in converting apple waste into environment-friendly packaging material. Research leader Yanyun Zhao studied apple pomace and other by-products from fruit and vegetable processing and juice and wine making. The team received a patent for the research and believe apple pomace can be the “main ingredient” for molded pulp packaging products, such as take-out containers and beverage cartons. Researchers must improve water resistance of pomace and other paper-based packaging to turn it into a viable alternative to plastic.[Image Credit: © Schlumpf98]

Copyright 2026 Business360, Inc.