CORPORATE ACTION

WWF Effort To Track Corporate Action On Plastic Waste Highlights Problem Areas

As part of its ‘No Plastic in Nature by 2030’ goal, the WWF brought together a consortium of companies and organizations under the ReSource banner to build a baseline understanding of plastics use and disposal, and to create a collaborative framework to shift to a more circular economy. It claims that as few as 100 companies have the potential to prevent roughly 50 million metric tons of the world's plastic waste by 2030.

As part of its ‘No Plastic in Nature by 2030’ goal, the WWF brought together a consortium of companies and organizations under the ReSource banner to build a baseline understanding of plastics use and disposal, and to create a collaborative framework to shift to a more circular economy. It claims that as few as 100 companies have the potential to prevent roughly 50 million metric tons of the world's plastic waste by 2030.For its inaugural report – TRANSPARENT 2020 – ReSource worked with ‘Principal Members’ Keurig Dr. Pepper, McDonald’s, Procter & Gamble, Starbucks, and The Coca-Cola Company using 2018 data to create a baseline of plastics use and disposal.

These companies prepared and released detailed data on their plastics use which provides a window into the types of plastics used, geographic breakdowns and estimated disposal endpoint. These data foreshadow the level of clarity that will soon be expected of other companies.

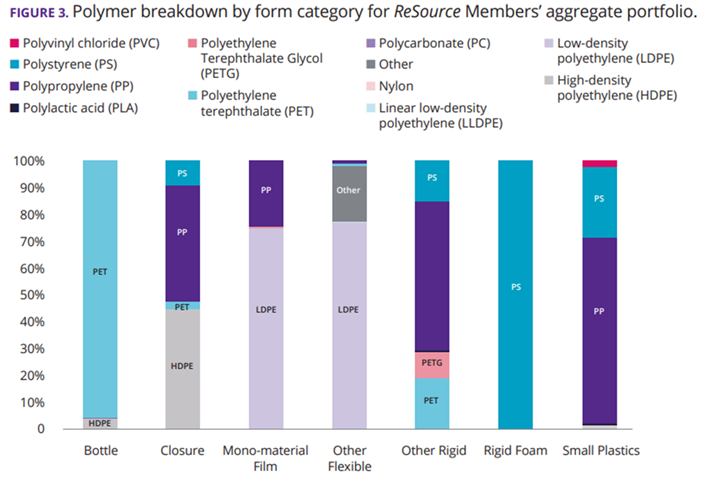

Data in the report reveals a number of findings. The polymer breakdown makes plain the range and diversity of plastics used by CPGs:

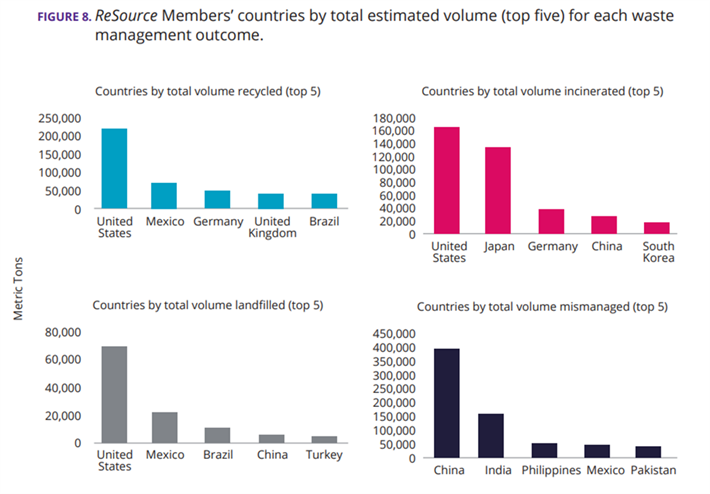

For the US, geographic data highlight the high tonnage volumes as well as the high levels of landfill and incineration (note: the footprints of participating companies is heavily skewed to this region). Also, East Asia is a hot spot for mismanagement (53%). The large footprint in China, where mismanaged rates are 76%, contributes to this region having the highest total tonnage of estimated mismanaged plastics.

The report makes a number of practical recommendations:

- Eliminate unnecessary plastics: reduce and redesign small plastic, including familiar, difficult-to-recycle items like utensils, coffee stirrers, straws, and closures since these are largely excluded from recycling streams

- Invest in sustainable production: such as solutions that reduce virgin plastic use and increase recycled or sustainably sourced biobased content (across the five companies, the average amount of recycled content used is only 8%)

- Double the global recycling rate: the report highlights potential in the US, which has high sales volumes, limited recycling infrastructure and high landfill rate (72%). It stresses the need to recycle polypropylene (used for bottle caps, yogurt caps, prescription bottles, or the other ‘stronger’ types of plastic) that is close to zero in the US currently

- Work to fill critical data gaps: there remain many important data gaps to address, along with a need for better mechanisms to coordinate data collection with common standards, and to share best practices

CORPORATE ACTION: Coca-Cola

Coca-Cola Amatil Plans Plastic Bottle Recycling Plant In Indonesia

Coca-Cola Amatil has contracted with plastic packaging maker Dynapack Asia to conduct a feasibility study on building a plastic bottle recycling plant in Indonesia. The company hopes to cut consumption of new plastic resin by as much as 25,000 tons a year by 2022 by using recycled plastic. Indonesia is the world’s second-largest marine plastic debris polluter behind China, a 2015 study reported. The country plans to slash plastic waste output by 70 percent by 2025 as its contribution to the global National Plastic Action Partnership (NPAP).[Image Credit: © Coca-Cola Amatil Limited]

Coca-Cola Amatil has contracted with plastic packaging maker Dynapack Asia to conduct a feasibility study on building a plastic bottle recycling plant in Indonesia. The company hopes to cut consumption of new plastic resin by as much as 25,000 tons a year by 2022 by using recycled plastic. Indonesia is the world’s second-largest marine plastic debris polluter behind China, a 2015 study reported. The country plans to slash plastic waste output by 70 percent by 2025 as its contribution to the global National Plastic Action Partnership (NPAP).[Image Credit: © Coca-Cola Amatil Limited]

Developers Of Plant-Based Biodegradable Drinks Bottles See Commercialization By 2023

Although the technology is still several years from the marketplace, Coca-Cola and Danish brewer Carlsberg have invested in the Paper Bottle Project, whose goal is to replace plastic bottles with a sturdy all-plant material that completely decomposes within one year. The project is run by the Paper Bottle Company (Pabaco), a joint venture of paper packaging developer BillerudKorsnäs and Austrian plastics manufacturer ALPLA. Dutch biochemical company Avantium is developing a plant-based material (PEF) strong enough to hold drinks and still biodegradable within one year, by 2023. Carlsberg was an early supporter of the technology.[Image Credit: © WebWire/The Coca-Cola Company]

Although the technology is still several years from the marketplace, Coca-Cola and Danish brewer Carlsberg have invested in the Paper Bottle Project, whose goal is to replace plastic bottles with a sturdy all-plant material that completely decomposes within one year. The project is run by the Paper Bottle Company (Pabaco), a joint venture of paper packaging developer BillerudKorsnäs and Austrian plastics manufacturer ALPLA. Dutch biochemical company Avantium is developing a plant-based material (PEF) strong enough to hold drinks and still biodegradable within one year, by 2023. Carlsberg was an early supporter of the technology.[Image Credit: © WebWire/The Coca-Cola Company]

CORPORATE ACTION: Natura Brasil

Natura Shares Some Of Its Preferred Plastic Waste Elimination Solutions

Following the launch in 2019 of its Natura Innovation Challenge - Zero Waste Packaging, Natura has made available a set of solutions to help eliminate plastic waste.

Following the launch in 2019 of its Natura Innovation Challenge - Zero Waste Packaging, Natura has made available a set of solutions to help eliminate plastic waste.The company said it analyzed over 570 solutions from around the world that addressed the issue in different ways, including rethinking packaging, logistics and business models. It was Natura's largest ever open innovation exercise.

Natura has made available 38 selected solutions on a G Drive. However, the list contains no assessment or criteria and looks to be a compilation of stated solutions as prepared by the innovator, sometimes in English but mostly in Portuguese.

The company indicated that three projects have been selected and are now at the test phase in the company, but it is not clear which projects these are.[Image Credit: © Natura]

CORPORATE ACTION: Nestlé

Nestlé Lays Out Current Commitments But Is Vague On Some Strategies

In a recent interview, Nestlé’s Global Head of Sustainable Packaging, Véronique Cremades-Mathis, highlighted various initiatives and commitments the company has made.

In a recent interview, Nestlé’s Global Head of Sustainable Packaging, Véronique Cremades-Mathis, highlighted various initiatives and commitments the company has made.She points out that 87% of all its packaging is already either recyclable or reusable and that it committed to reducing use of virgin plastics by one-third by 2025.

Cremades-Mathis also pointed out that even though it is considerably more costly than virgin plastic, the company is committed to sourcing up to 2 million metric tons of food-grade recycled plastics and allocating more than US$1.56 billion to pay a premium for the materials between now and 2025. It is doing this in the hope of creating a virtuous circle in the recycling industry.

And since recycling is infeasible without a more robust recycling industry, Nestle is working with governments, industry bodies and competitors to boost recycling infrastructure.

Notably, in a separate press release, Nestlé Waters states that by 2030 the company aims to collect as many plastic bottles as it produces. It is not clear how it will achieve this. While recycling rates in the EU are high and could reach 90% collection for recycling of bottles and caps by 2025, in most other jurisdictions they are much lower. Only by actively collecting bottles produced by other suppliers (or paying companies to do that) does it seem feasible for Nestlé Waters to collect as many plastic bottles as it produces.[Image Credit: © Nestlé]

Nescafé Is Piloting Refillable/Reusable Options In Coffee and Petcare

Nestlé is trialing reusable and refillable in-store options for Purina cat food and Nescafé soluble coffee, inviting shoppers to bring their own containers. It piloted the scheme in three of its outlets in Switzerland, and the trial is being extended to more locations. It has also announced a pilot for its Refill Plus water dispenser, which offers 64 flavor options, and is working with TerraCycle’s Loop platform in the US and, soon, in France. Also, Nescafé and Milo brands are offering mini dispensers in the out-of-home channel in a number of markets.[Image Credit: © Nestlé]

Nestlé is trialing reusable and refillable in-store options for Purina cat food and Nescafé soluble coffee, inviting shoppers to bring their own containers. It piloted the scheme in three of its outlets in Switzerland, and the trial is being extended to more locations. It has also announced a pilot for its Refill Plus water dispenser, which offers 64 flavor options, and is working with TerraCycle’s Loop platform in the US and, soon, in France. Also, Nescafé and Milo brands are offering mini dispensers in the out-of-home channel in a number of markets.[Image Credit: © Nestlé]

CORPORATE ACTION: Other

Flipkart Cuts Plastic Packaging By Half

Bulldog Launched Its Second Bamboo Razor, This Time For Sensitive Skin

British skincare brand bulldog has launched a second bamboo razor, for sensitive skin, following the 2018 launch of its Original razor product. The new razor features a water-resistant bamboo handle and steel blade that pivots. Caroline Mallet of Bulldog Skincare said the company had identified a “lack of focus on the environment” within the razor category, with a lot of plastic used in the product and packaging. Launched in the UK, Bulldog’s Original razor is now sold in 12 markets.[Image Credit: © Bull Dog]

British skincare brand bulldog has launched a second bamboo razor, for sensitive skin, following the 2018 launch of its Original razor product. The new razor features a water-resistant bamboo handle and steel blade that pivots. Caroline Mallet of Bulldog Skincare said the company had identified a “lack of focus on the environment” within the razor category, with a lot of plastic used in the product and packaging. Launched in the UK, Bulldog’s Original razor is now sold in 12 markets.[Image Credit: © Bull Dog]

CAMPAIGNS, COMMITMENTS & NGOs

A New Study Puts Forward Recommendations To Support Consumers In Their Recycling Efforts

- Businesses to follow the Guidelines for Providing Product Sustainability Information in their communications around plastic packaging to overcome the large differences that exist today in the “reliability, relevance, clarity, transparency and accessibility of labels and claims on plastic packaging”.

- Definitions surrounding content and reusability of plastic must be standardized globally.

- Definitions and requirements used in standards for recyclability, compostability and biodegradability need to be more consistent with real world conditions and the limitations of consumer response.

- The ‘chasing arrows’ symbol should only be used to signify recyclability, and the design of labels and logos must be clearer to help consumers better understand what is required

- Companies should adopt well-designed recyclability labels, and organizations responsible for the labels must “align their requirements to reduce consumer confusion”.

MARKET NEWS

Recycled Content Commitments Under Pressure From Low Oil Prices

Falling oil prices from market pressures, including those resulting from the economic impact of COVID-19, have pushed virgin plastic prices lower, making the post-consumer recycled plastic pledges by companies under The Ellen Macarthur Foundation’s New Plastics Economy Global Commitment even more challenging than they were already. In North America, post-consumer plastic supply can only satisfy 6% of demand, far below companies’ typical target of 25% by 2025.

With the economics shifting even further in favour of virgin plastic, recyclers are concerned about companies retreating from their commitments, forcing down the price of PCR material. The pandemic has also diluted some of the regulations and motivation that had started to introduce momentum into the PCR market. Some of the large corporations, like Coca-Cola and Unilever, are keen to reassure the market that these short-term issues won’t sway them from longer-term goals, but they might be hampered by the lack of available rPET, for example.

To create a more secure future for PCR, the market needs innovation in recycling methods and processes, especially for some of the harder-to-recycle plastics; a more robust foundation, possibly from commitments to multi-year contracts that give suppliers the confidence to invest; supporting policy to build recycling infrastructure; a more even playing field, in light of subsidies paid to the fossil fuel industry; and new models, such as reduction and re-use, including TerraCycle's Loop platform.

With the economics shifting even further in favour of virgin plastic, recyclers are concerned about companies retreating from their commitments, forcing down the price of PCR material. The pandemic has also diluted some of the regulations and motivation that had started to introduce momentum into the PCR market. Some of the large corporations, like Coca-Cola and Unilever, are keen to reassure the market that these short-term issues won’t sway them from longer-term goals, but they might be hampered by the lack of available rPET, for example.

To create a more secure future for PCR, the market needs innovation in recycling methods and processes, especially for some of the harder-to-recycle plastics; a more robust foundation, possibly from commitments to multi-year contracts that give suppliers the confidence to invest; supporting policy to build recycling infrastructure; a more even playing field, in light of subsidies paid to the fossil fuel industry; and new models, such as reduction and re-use, including TerraCycle's Loop platform.

POLICY, REGULATION & LEGAL

Trade Associations And Campaigners Push For UK Ban On “Oxo-Degradable” Plastics

A coalition of trade associations and campaign groups petitioned the UK government to ban oxo degradable/oxo biodegradable/oxo fragmentable plastics. These plastics are banned under EU law but with the UK set to leave the EU it needs to address the matter directly.

Signatories say that overwhelming scientific evidence demonstrates that these plastics are not biodegradable. Instead, oxo-additives merely accelerate the degradation from macroplastics into microplastics, exacerbating plastics pollution.

Signatories include the Anaerobic Digestion and Bioresources Association (ADBA), the Environmental Services Association (ESA), the Foodservice Packaging Association (FPA), the REA, Greenpeace, A Plastic Planet and Recoup.

Signatories say that overwhelming scientific evidence demonstrates that these plastics are not biodegradable. Instead, oxo-additives merely accelerate the degradation from macroplastics into microplastics, exacerbating plastics pollution.

Signatories include the Anaerobic Digestion and Bioresources Association (ADBA), the Environmental Services Association (ESA), the Foodservice Packaging Association (FPA), the REA, Greenpeace, A Plastic Planet and Recoup.

INNOVATION & TECHNOLOGY

ECO Bowl For Fresh Food Launched Using Up To 85% Less Plastic

Packing companies DS Smith and MULTIVAC worked together to launch an ECO Bowl they claims uses up to 85% less plastic compared to a traditional plastic tray.

Packing companies DS Smith and MULTIVAC worked together to launch an ECO Bowl they claims uses up to 85% less plastic compared to a traditional plastic tray.The ECO Bowl is made with 100% recycled paper and has a corrugated construction to retain its rigidity. It can be transparent or have fully printed surfaces and does not need sleeves or labels. It is designed to run on MULTIVAC thermoforming packaging machines and tray sealers.

In a press release, MULTIVAC said ECO Bowl has already been tested in the market with amidori, the German producer of plant-based meat alternatives, at the end of 2019.[Image Credit: © DS Smith]

Four Plastic Waste Schemes Win Grants In The UK

- Impact Solutions and Scottish Plastic Recycling Centre of Excellence – PolyChrome, a new recycling technology to remove color and additives from polyethylene and polypropylene.

- Luxus and the Technology Research Centre – a collaborative project that uses artificial intelligence and machine learning to identify the best way to use recycled materials cost-effectively.

- Unilever and University of Liverpool – a novel packaging solution for the Domestos bleach brand, using over 70% post-consumer recycled in high density polyethylene bottles. It has the potential to be used for other home care products, including for the professional cleaning category.

- Technology Research Centre and RPC Containers Ltd – a way of separating contaminated film to fully recover polyethylene, polypropylene, polyethylene terephthalate and aluminium from layered packaging, such as in tubs, cups and semi-rigid trays.

Advances In Sustainable Plastics Continues

Despite restrictions imposed by coronavirus, innovations in sustainable packaging are continuing, as shown by an online review by ThePackHub. Here are a few interesting food applications that center on plastic elimination, reduction or improved recyclability.

Despite restrictions imposed by coronavirus, innovations in sustainable packaging are continuing, as shown by an online review by ThePackHub. Here are a few interesting food applications that center on plastic elimination, reduction or improved recyclability. Gualapack launched Pouch5, a range of 100% mono-material standup pouches, recyclable as polypropylene (PP) within existing PP streams.

The company believes its pouches are suitable for drinks and juices, fruit puree and yoghurt, but also for beauty and personal care products – for example, soap refills or face masks – and home care, like detergents. Gualapack says that its monomaterial standup pouches have already been adopted by two Nestlé baby food brands: Gerber in the USA and Piltti in Finland.

Schur Flexibles developed a recyclable, high-performance polyolefin film that can be combined with the companies FlexTop(re) top film that enables the amount of plastics used to be reduced considerably.

In Germany, HERMANN used it to reduce the plastics portion of existing packaging by about 80%. The company says that even though the amount of plastic used is much lower and recyclable, it offers the highest product safety and reliable sealing properties, excellent peelability, and is also suitable for pasteurization.

DalterFood Group of Italy launched a range of hard cheeses in a compostable and biodegradable film. Developed by subsidiary. Dalter Alimentari, the films are made with reprocessed “residues of agricultural products” and can be disposed of in food waste.[Image Credit: © Images from company sites]

RESEARCH

Studies Suggest Ocean Microplastic At Least Double Previous Estimates And Entering Food Chain

A study using finer meshed nets than used in previous studies found microplastic levels to be vastly underestimated. Waterborne microplastic sampling is typically undertaken using 333 μm mesh nets but samples captured with a 100 μm mesh yielded 2.5x the amount of microplastic, and 10x compared to 500 μm mesh nets. Researchers suggest total ocean microplastic is 12tn-125tn (tn=trillion) particles rather than 5tn-50tn as previously estimated. This suggests microplastic is likely more numerous than zooplankton, among the most abundant of species. Since they are the same size as zooplankton, researchers believe microplastics and may play a role in affect the marine food chain and play a role in regulating the global climate. Analysis shows that plastics captured come mainly from fibers from textiles such as ropes, nets and clothing.

A separate study looked at plastic in fecal matter and regurgitates of free‐living Eurasian dippers to assess plastic transfer through food webs. The study found plastic particles present in 50% of dipper regurgitates and in 45% of fecal pellets from both adults and chicks. This study is one of the first to show plastic transfer through food webs in natural freshwater environments.[Image Credit: © Pixabay, MrsBrown]

Worms Help Scientists Identify Bacteria and Enzymes That Degrade Polystyrene

.png&width=125&height=117) Recent studies showed that mealworms (larvae of Tenebrio molitor) and superworms (Zophobas atratus) can digest and degrade polystyrene. A new study placed 50 superworms (about 2 inches long and commonly found in pet stores as a food source for reptiles and fish) in a container with polystyrene as the sole carbon source. After three weeks, the worms had digested ~70% of the plastic. Researchers identifed the gut bacteria that grows directly on the plastic to degrade it. They also identified an enzyme from the bacteria, serine hydrolase, which looks responsible for most of the biodegradation. Researchers believe that this enzyme, or the bacteria that produce it, could help break down waste polystyrene at scale.[Image Credit: © Pixabay, Hans]

Recent studies showed that mealworms (larvae of Tenebrio molitor) and superworms (Zophobas atratus) can digest and degrade polystyrene. A new study placed 50 superworms (about 2 inches long and commonly found in pet stores as a food source for reptiles and fish) in a container with polystyrene as the sole carbon source. After three weeks, the worms had digested ~70% of the plastic. Researchers identifed the gut bacteria that grows directly on the plastic to degrade it. They also identified an enzyme from the bacteria, serine hydrolase, which looks responsible for most of the biodegradation. Researchers believe that this enzyme, or the bacteria that produce it, could help break down waste polystyrene at scale.[Image Credit: © Pixabay, Hans]

The Dieline Awards Showcase Non-Plastic Packaging Concepts

The Plastic-Free Innovation Awards from Dieline and A Plastic Planet aims to highlight innovations that rethink packaging. APP’s Sian Sutherland discusses the top three 2020 winners:

#1: Pearl - fiber-based shell-shaped containers to replace single-use plastic sample packets used for beauty and skincare products.

#2: Puck – a round child-proof screw-top tin for cannabis products.

# 3: Hello - recyclable toothpaste tubes have proved elusive, and squeezable toothpaste has been difficult to replace, but Hello has launched chewable toothpaste in a cylindrical tin.

#1: Pearl - fiber-based shell-shaped containers to replace single-use plastic sample packets used for beauty and skincare products.

#2: Puck – a round child-proof screw-top tin for cannabis products.

# 3: Hello - recyclable toothpaste tubes have proved elusive, and squeezable toothpaste has been difficult to replace, but Hello has launched chewable toothpaste in a cylindrical tin.

Copyright 2026 Business360, Inc.